Understanding Multi-Fill volumetric fillers

Did you know that volumetric fillers reduce packaging time and costs? Using labor to fill foods into containers is a thing of the past. Production lines now perform these filling requirements with technology and machines. Labor is still essential but machines work faster and create a more efficient manner of filling than manual methods.

A volumetric filler can have many benefits to your packaging and

production process. Multi-Fill has various volumetric fillers available that are used to pack a wide range of products. In this article, we discuss how volumetric fillers can assist companies, especially businesses in the food industry. We also provide examples of videos of Multi-Fill filler machines to help guide your workforce.

1. What is a volumetric filler machine?

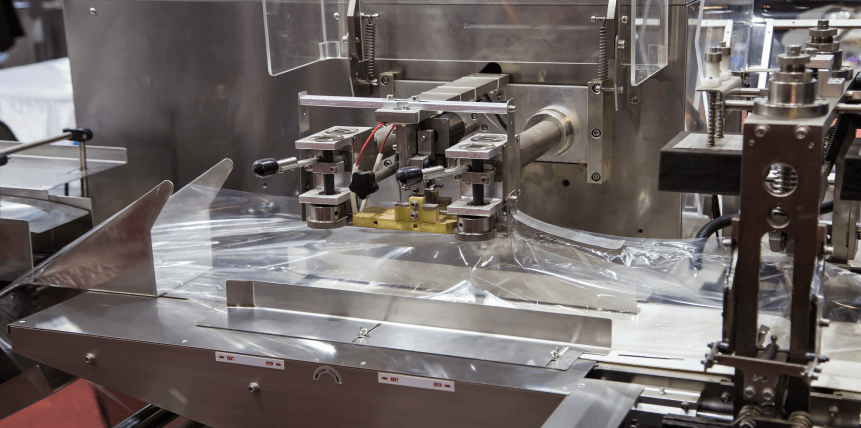

A volumetric filler machine is a

machine that fills food into containers. They come in various sizes and types. Each type of machine is designed to specifically fit the characteristics of both the food to be deposited and the container a production line is working with. A volumetric filler fill any free flowing granular food, like rice, salads, chopped vegetables, grains, legumes, and so on. Various businesses, retailers and wholesalers use their machines to help them efficiently and quickly fill their products to consumers or clients.

Multi-Fill filling machines are the industry standard for filling cooked rice and salads, which are impossible to fill with other machines. The machines are designed with innovative filling properties to distribute accurate amounts of food products into containers, bowls, cups, and trays.

Most volumetric fillers, especially Multi-Fill machines are easier to use and require few manual adjustments. The machines make life easier for the operator as it is designed for smooth and swift filling. Depending on your business or production line, a specific filling machine can help you produce more without having to hire more labor.

2. Types of volumetric fillers

There are different types of

volumetric filling machines. For the purpose of understanding how fillers work, we will look at the main types of volumetric filling machines used in production lines. These are pump filling, gravity-fed, piston filling systems, and solid-filling machines. Machines can be

semi-automatic or automatic. Each type provides the same function but your business goals and production line will factor in when choosing a machine that works best for you.

- Pump filling machines

A pump filling machine will move your container or packaging through its gears and use a pump to fill these containers. These machines are used in production lines requiring heavy volumes of liquid filling. They work well for creamy and liquid products as the machines reduce clumping and jamming. Sensitive liquids such as hazardous liquids are often used for pump filling machines as the tubes are easily replaced and safe to use.

- Gravity-fed machines

These machines use systems that use gravity to fill into containers. The product is forced out the filling head by gravity-pressured tubes. Gravity-fed machines are used for releasing accurate amounts quickly and quietly.

- Piston-filling machines

A piston filler works with a valve and cylinder. These are used for liquid only. The product is forced through a nozzle into the cylinder. Piston fillers are commonly used for thick liquids and large particles.

- Solid filling machines

Solid filling machines are similar to gravity-fed machines. They are designed to fill dry products such as rice and pasta. Multi-Fill provides these machines for ready-made food that are used in different industries such as the food industry to supply food products to wholesalers and food markets.

3. Benefits of volumetric fillers

There are numerous advantages of adding a volumetric filler to your production line. Here are just some of the

main benefits to consider:

- Your business can increase the volume of production without increasing labor or the costs involved in having to train new employees.

- Volumetric fillers are highly consistent. Unlike human operators, they deposit the same amount into every container, and they do so very quickly. Some can fill up to 120 containers every minute.

- Volumetric fillers make life easier for the operator as they don’t have to hand feed separate items, giving them time to focus on other aspects of packaging.

- They offer flexibility as volumetric machines can handle a variety of containers, bottles, jars, and plastic packaging. Your business can use it regardless of what packaging item you choose.

- Labor is important but machines are efficient as they increase speed and productivity. You can fill hundreds of bowls in a matter of minutes.

- Volumetric machines are generally easy to use. Some require operators to be present to perform manual functions (such as setting the container under the nozzle and adjusting the volume) but automatic machines are easy to set up and do not need constant supervision.

- The fillers increase the level of food quality that your business is supplying as it ensures that no risk of human contamination occurs.

- Volumetric fillers are easy to clean as most parts are moveable.

- The cost you save on production will easily outweigh the cost you spend on the machine.

4. How to choose a packing machines manufacturer

Volumetric fillers are a good investment for almost any factory line. The money your company saves on production and packaging time will be far greater than the costs involved should your business continue to use solely hand-feeding methods. Whether you are new to the industry or a professional company requiring cost-effective and efficient ways for your packaging and filling requirements, it is important to do your research when it comes to picking a filling machine.

There are many packing machines for sale online but it is important to choose a reputable packing machine manufacturer such as Multi-Fill when choosing a machine for your company. By using a reputable company, you will ensure that you

receive quality manufactured machines made by experts with years of study and experience in production lines. You will also save yourself the costs involved in repairing badly manufactured machines or used volumetric fillers.

5. How to choose a volumetric filler

Choosing the right machine will depend on your business needs. If you are looking for a machine for food and solid or larger particles, Multi-Fill is your best bet. We provide a range of volumetric fillers,

as well as upgrades, and equipment needed such as a patent distribution system, batch feeding hopper, and parts cart. We have

offices worldwide and follow a guarantee of excellence. Our filler machines include a quality line of products, such as the Multi-Fill MPFMP-060 volumetric filler, Multi-Fill MPFSC-120 volumetric filler, and Multi-Fill MPFSh-075.

It is always worth doing a test with your product on the machine before you buy one. Product tests can reveal any difficulties with your product and the machine you’re considering, and they give you a chance to see in person how well the machines will perform. When you choose a machine from Multi-Fill, you receive excellent

workmanship service from a team that works with you to manufacture a machine to handle your production line.

Now that you have an understanding of volumetric fillers, you are better equipped to make your choice. If you have trouble choosing a specific machine for your type of product, Multi-Fill can help. Our gracious team has rounded up some FAQs for choosing a volumetric filler machine. Be sure to have a look at your Youtube videos below for each design. You can use these videos as tutorials for your employees or workforce in assisting them to understand how filters work and how to clean and operate them. Subscribe to your Youtube channel for more videos.

Types of volumetric fillers for different uses

There are many volumetric filters available for different products, product lines, and volumes. The Multi-Fill MPFMP-060 volumetric filler, Multi-Fill MPFSC-120 volumetric filler, and Multi-Fill MPFSH-075 are

examples of fillers that can be used for a variety of product distributions. Each filler is designed to fill containers, bowls, or packaging with food such as pasta or cooked rice.

Machines are designed to be plug and play, so they can integrate into most existing lines. Multi-Fill also specifically manufactures filler machines to manage all sorts of foods and can design machines according to your workspace needs.

Using a volumetric filler to fill salad bowls

Salad is made easy with the Multi-Fill MPFMP-060 volumetric filler. It is a semi-automatic machine used to deposit food such as barley into salad bowls. The machine can full up to 50-60 containers per minute and has an integrated parts cart. The MPFMP-060 volumetric filler is best for lower-speed production lines, such as those in the food industry that require low volumes of salads, but also suitable for research, development labs, and

pilot plant operations. To use the product, an operator needs to manually feed the tube, which makes this best for those who don’t require a large automatic system for their salad bowls.

Read more about the process and watch the

video here.

Using a volumetric filler to fill bowls

Different types of volumetric fillers can be used for different packaging. All of our products however come with volumetric pocket filler that dispenses clean and accurate portions of food into a variety of bowls. Even difficult-to-fill bowls are easy to fill with our range of filler machines.

Some food that you can fill into our bowls include:

- Cooked rice

- Cooked pasta (long & short)

- Cut vegetables & fruit

- Ready-to-eat salads

- Cereal

- Surimi, shrimp, & shredded meats

Choosing the right machine for your bowls will depend upon the product, volume to fill, and operator. Find the Multi-Fill MPFMP-060 filler tutorial

here. You can view our Multi-Fill MPFSC-120 tutorial

here, and find the Multi-Fill MPFSH-075 link

here.

Using a volumetric filler to fill shredded meats

The

Multi-Fill MPFSh-075 volumetric filler can be used for many different food items. The machine is suitable for lower speeds, looser products, and smaller fill weights. Shredded meats fall into one of the most common ingredients that the machine can easily and quickly process. It is specifically designed to fill difficult to dispense shredded meat with its automatic product feeding. If you are in the food industry and supply a variety of shredded meat such as beef, chicken, or pork for cuisines, this machine can make life a lot easier.

Watch the tutorial for more info

here.

Using a volumetric filler to fill sauce trays

Sauce trays are not easy to fill as they can be small and things can get messy. A volumetric filler can make the process much cleaner and smoother by filling accurate amounts in small bowls. Sauce trays can be filled using the Multi-Fill

MPFSC-120 volumetric filler. depending on the volume you need to fill and your line configuration, you could fill up to 120 sauce trays per minute…or more. These trays are great for those requiring specific sauce trays for a specific food item or to add as separate dishes for customers.

Read more and watch the video

here.

Using a volumetric filler to two-compartment bowls

Two-compartment bowls might be used for packaging some products using certain machinery. The MPFSC-120 can be used to fill these bowls efficiently. The MPFSC-120 allows for automatic feeding of food products and can handle high speeds. It doesn’t matter if you need to use the filler for stickier products or small products, it can dispense accurate amounts of food into two-compartment bowls. Use the filler to pack larger volumes of food into these bowls for your customers.

Here’s a

link

to the Multi-Fill video for more info.

Using a volumetric filler to fill shell containers

Shell containers are commonly the plastic closed-up containers used by takeouts and other food places that provide ready-to-go food products. These can be difficult to fill, but thankfully there are volumetric fillers to help. Multi-fill fillers such as the MPFSC-120 volumetric filler can dispense clean and accurate portions of a wide variety of foods into these difficult-to-fill containers.

Fill your shell containers with cooked rice, cooked pasta (long and short), cut vegetables, cut fruit, refrigerated salads, etc. The list is endless.

Find the Multi-Fill video using our fillers for shell containers

here:

Using a volumetric filler to fill doypack bags

Doypack bags are commonly used to package certain products such as juices and detergents but recently these bags have been popular for solid food products such as cooked rice, nuts, and pet foods. Operators often have to open and seal these carefully to keep food fresh. With a volumetric filler, the packaging time is cut in half, as a filling machine carefully disposes of food such as rice into the bags with one swift motion. Watch

the video of how you can fill doypack bags with a Multi-Fill filler.

Contact us today or

view our website for more info on our range of Multi-Fill volumetric fillers!

Designing a food filling line: Product is king

Stay in Touch

Product news, tips, subscribe to our newsletter:

Contact Us

We will get back to you as soon as possible.

Please try again later.