How can Small Businesses Benefit from Using a Fill Machine?

In the fast-paced world of food processing, efficiency and precision are crucial, especially for small businesses striving to compete with larger operations. One way to level the playing field is by incorporating fill machines into your production line. These machines are more than just tools—they are transformative technologies that can redefine how your business operates.

From ensuring consistent product quality to maximizing productivity, fill machines provide small food processors with the means to scale up their operations without sacrificing accuracy or safety. In this article, we’ll explore the top five advantages of fill machines for small businesses, covering their benefits, applications, and considerations for choosing the right one. Whether you’re a buyer, technical manager, or engineer, this guide will show why investing in fill machines could be the best decision for your business.

Quick Takeaways

- Efficiency Boost: Fill machines improve production speed and help small businesses handle bulk orders seamlessly.

- Accuracy and Consistency: Delivering precise fill levels reduces waste and enhances customer satisfaction.

- Versatility for Growth: These machines accommodate various product types and packaging formats, supporting business expansion.

- Cost-Effectiveness: Reducing labor costs and product waste provides significant long-term savings.

- Enhanced Hygiene: Automated systems ensure compliance with safety standards, minimizing contamination risks.

What Are Fill Machines?

Definition and Purpose

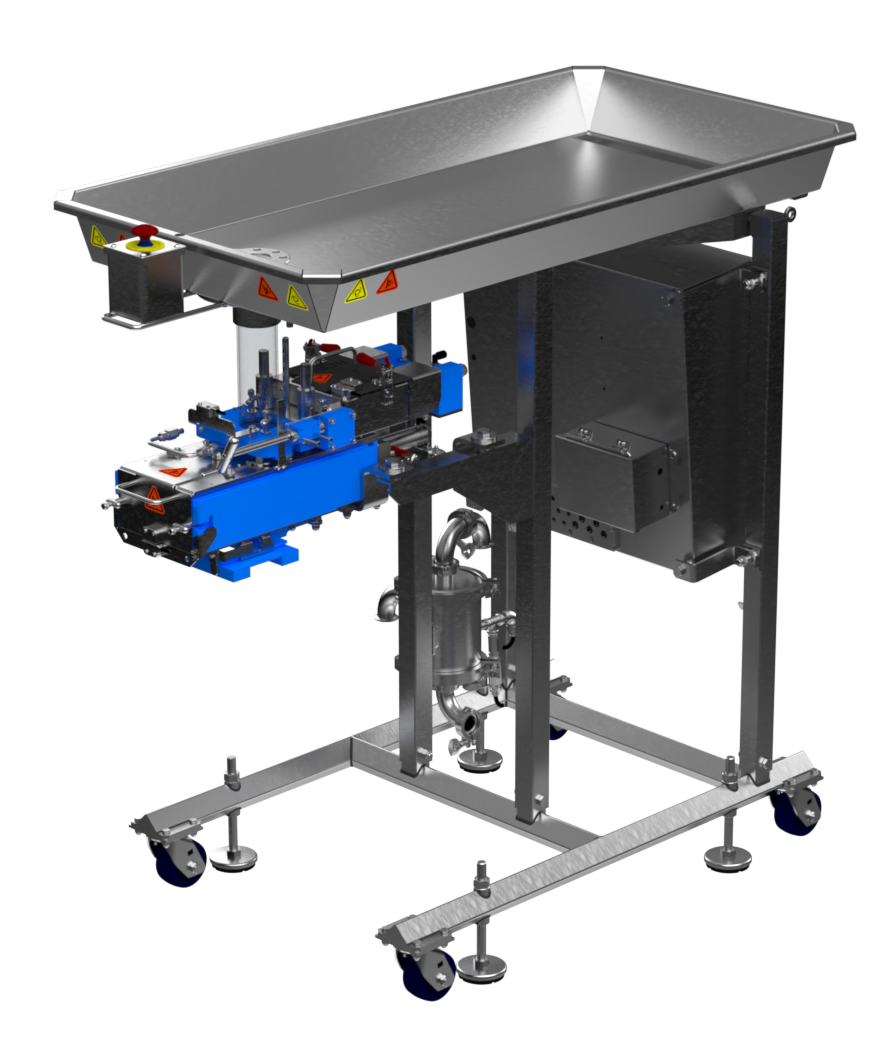

Fill machines are automated or semi-automated devices designed to dispense a specific quantity of product into containers, ensuring consistent portioning for food items like sauces, powders, and semi-solid products. Unlike manual methods, these machines deliver precision and speed, minimizing waste and maximizing efficiency.

Importance in the Food Processing Industry

In today’s competitive market, consistency and speed are non-negotiable. Imagine running a production line where every portion is slightly different—it not only creates consumer dissatisfaction but can also lead to regulatory scrutiny. Fill machines eliminate these risks while helping small businesses maintain product quality and meet growing demand.

Why Small Businesses Need Fill Machines

Challenges in Manual Filling

For small food businesses, manual filling can quickly become a bottleneck. Uneven portion sizes, inconsistent production rates, and employee fatigue limit growth potential. Automating this process with fill machines frees up time and reduces errors, ensuring smooth operations.

The Growing Demand for Automation

Automation is no longer just for large corporations. Advances in technology have made cost-effective filling solutions for artisanal food producers accessible, allowing small businesses to streamline production and meet customer expectations without overextending resources.

Types of Fill Machines

Volumetric Fillers

Perfect for liquids and semi-liquids like soups or sauces, volumetric fillers ensure precise portions, enhancing customer satisfaction and regulatory compliance.

Liquid and Overflow Fillers

Liquid fillers are ideal for thinner products like oils, while overflow fillers create a uniform appearance, perfect for transparent containers.

Piston and Auger Fillers

Piston fillers handle thick products like peanut butter, while auger fillers are designed for powders such as spices, enabling product line diversity without additional equipment.

Top 5 Advantages of Fill Machines for Small Businesses

1. Boosting Operational Efficiency

- Fill machines increase production speed, helping small businesses handle bulk orders effortlessly.

- By automating repetitive tasks, they allow your team to focus on innovation and customer service.

2. Enhancing Accuracy and Reducing Waste

- These machines provide consistent fill levels, minimizing product waste and overfills.

- Every portion is identical, ensuring customer satisfaction and compliance with packaging standards.

3. Versatility Across Products

- Fill machines handle a wide range of products, from liquids to semi-solids, making them a versatile investment.

- They adapt to various container sizes and formats, catering to dynamic market demands.

4. Improved Hygiene and Food Safety

- Automated systems meet food safety standards by reducing human contact with products.

- Features like self-cleaning cycles enhance cleanliness between batches, protecting consumers and your brand.

5. Cost Savings in the Long Run

- By lowering labor costs and reducing waste, fill machines provide significant financial savings over time.

- While the upfront cost may seem high, the long-term benefits quickly offset the investment.

How to Choose the Right Fill Machine

Factors to Consider

- Product Characteristics: Viscosity, texture, and particulate content.

- Production Requirements: Batch sizes and output volume.

- Budget Constraints: Initial investment and maintenance costs.

Regulatory Compliance

Ensure the machine meets food safety standards and has necessary certifications to align with industry regulations.

FAQs About Fill Machines for Small Businesses

1. What are the main benefits of using fill machines for small food processing businesses?

A: Fill machines improve production efficiency, ensure consistent product portions, and reduce labor costs. They also enhance hygiene by minimizing human contact with food products, making them an essential tool for small businesses aiming to scale up.

2. How do I choose the right filling machine for my product?

A: Selecting the right fill machine depends on your product’s characteristics, such as viscosity, texture, and particulate content. For example, liquid fillers work best for beverages, while auger fillers are ideal for powders. Consider your production volume and budget to find a machine that meets your needs.

3. Are fill machines suitable for small-scale production?

A: Yes! Many fill machines are designed specifically for small-scale production line equipment, offering compact sizes and customizable features. These machines provide cost-effective solutions that allow small businesses to automate without overextending their resources.

4. What types of products can fill machines handle?

A: Modern fill machines are versatile, accommodating liquids, powders, semi-solids, and chunky products like salsas. By investing in versatile filling systems, small businesses can expand their product range without purchasing multiple machines.

5. How much maintenance do fill machines require?

A: Maintenance varies by machine type, but most modern fill machines are low-maintenance and feature easy cleaning protocols. Look for machines with self-cleaning or washdown capabilities to simplify upkeep and ensure long-term reliability.

For small businesses in the food processing industry, fill machines are transformative technologies that enhance efficiency, accuracy, and hygiene. From reducing product waste to enabling scalability, these machines provide small food processors with the tools to compete with larger players while maintaining product quality.

If you’re a buyer, technical manager, or engineer, don’t let outdated methods hold your business back. Embrace automation to optimize your production line and grow your operations. Visit Multi-Fill.com to find the perfect fill machine for your business today!

References

1. Multi-Fill. “Food Filling Machines pouch & tray filling systems.” (multi-fill.com)

2. Multi-Fill. “Filling Machines 101 - How Do Filling Machines Work?” (multi-fill.com)

3. Multi-Fill. “Understanding volumetric filling machines.” (multi-fill.com)

Designing a food filling line: Product is king