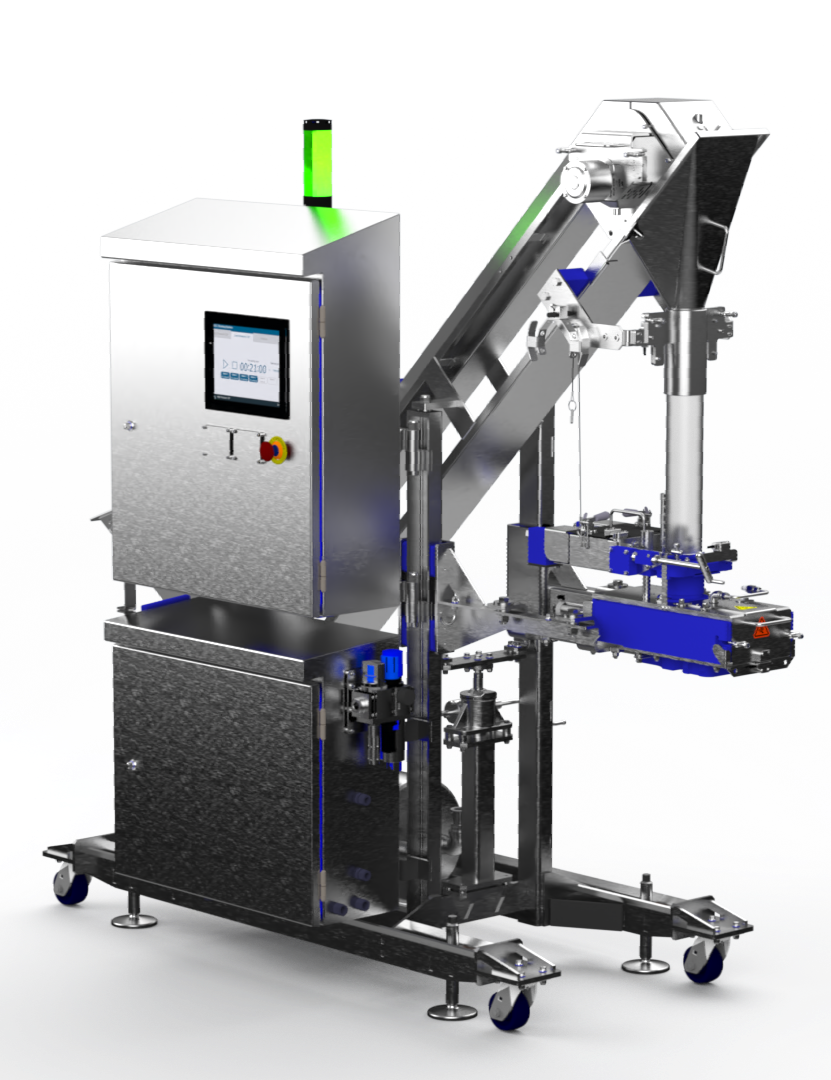

Volumetric Filling Machines

At Multi-Fill, we design and build food-filling solutions that seamlessly integrate into your production line. Whether you're filling pasta, rice, or diced proteins, our machines are engineered for efficiency, precision, and hygiene.

Every production facility has unique needs, so it is critical to have machines that are adaptable to different products, speeds, and packaging formats.

By focusing on reliability and ease of maintenance, we help you maximize output while minimizing downtime, ensuring your operation runs smoothly and profitably.

Our Solutions

Streamline Your Food Production

You’re determined to streamline your food production, and finding the right filling system is key. With Multi-Fill’s custom volumetric fillers, you can design a solution that fits your exact needs—whether you’re handling diced vegetables, sticky sauces, or delicate pasta. You’re in charge of creating a seamless process, and Multi-Fill’s turnkey support makes it happen, from consultation to installation. Imagine a filling system that boosts your output while keeping everything running smoothly.

Your operation is unique, with specific product textures, container sizes, and production goals. That’s why you need equipment that adapts to you—not the other way around. Multi-Fill’s customizable fillers let you tweak fill volumes, speeds, and setups to match your vision. With their expertise backing you up, you can confidently expand your product range and deliver top-quality goods that keep your customers coming back.

Supercharge Your Efficiency with Next-Level Filling Equipment

You’re always looking for ways to push your production further, and the right technology makes all the difference. Multi-Fill’s state-of-the-art volumetric fillers give you the edge, handling everything from chunky ingredients to smooth purees with pinpoint accuracy. You can scale up your output or fine-tune your process, knowing these automated systems are built to keep pace with your ambitions.

Picture this: Your throughput soars thanks to high-speed filling that eliminates bottlenecks. Your product quality stays consistent, cutting waste and keeping standards high. Plus, with durable, low-maintenance equipment, you minimize downtime and keep your line humming. Multi-Fill’s cutting-edge tools empower you to elevate your operation and boost your bottom line like never before.

Master Food Safety and Performance in Your Facility

Maintaining a clean and safe production environment in your factory is non-negotiable—you know the stakes are high. Multi-Fill’s volumetric fillers are designed with your priorities in mind, featuring hygienic surfaces and sanitary components that help you fight contamination risks. You can trust these systems to perform in tough conditions, ensuring your products meet the strictest safety standards without slowing you down.

You’re focused on maximizing your Overall Equipment Effectiveness (OEE), and Multi-Fill’s smart design helps you get there. With quick-clean features and reliable performance, you spend less time on maintenance and more time producing. Their intuitive, robust equipment puts you in the driver’s seat, letting you deliver standout food products with confidence in a competitive market.