Downtime Happens…Your Food Filling Equipment Doesn’t Have to Be the Problem

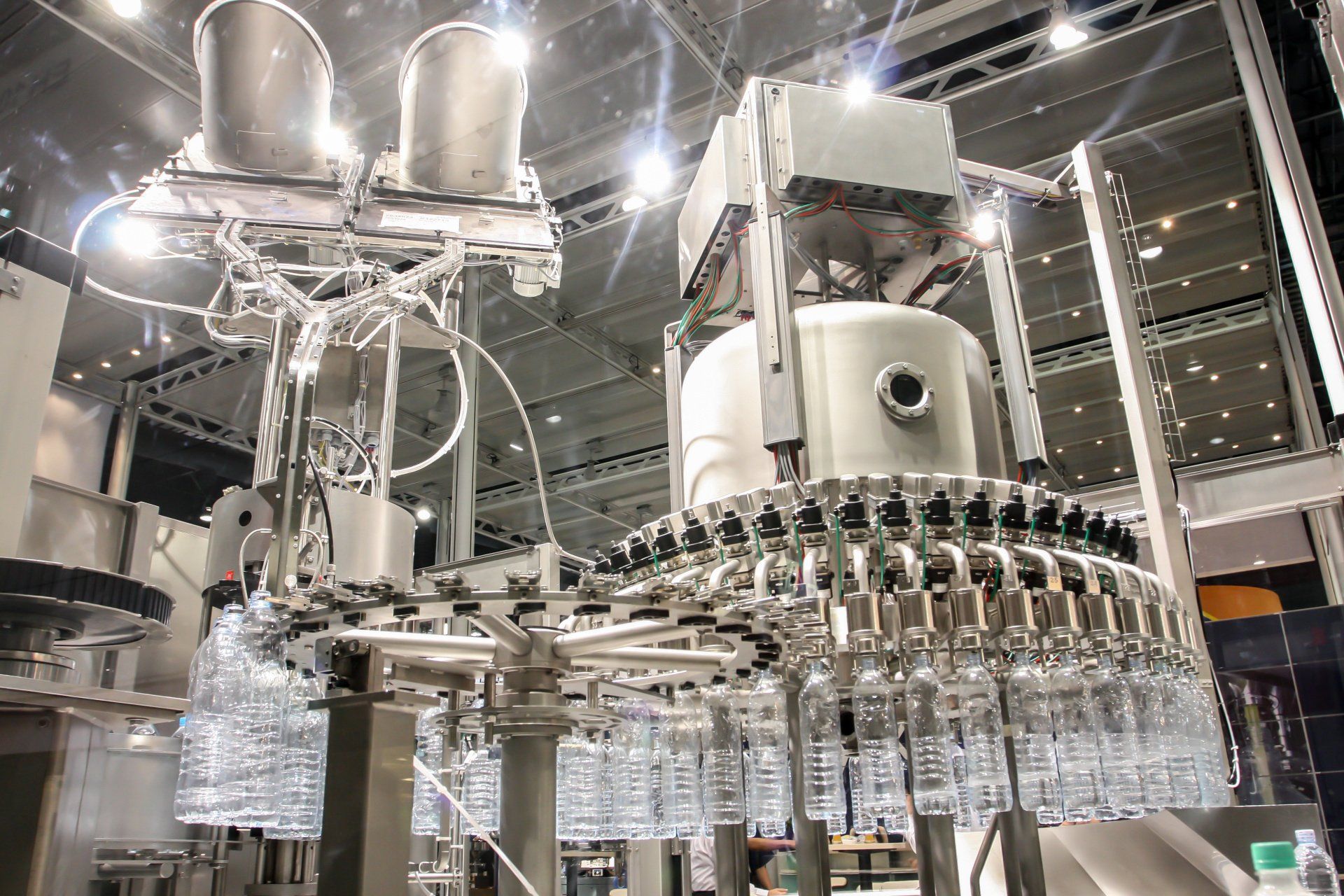

In the food industry, as in almost every business, downtime is inevitable and usually necessary. However, your food filling equipment need never be the reason for a filling line to come to a halt. New designs of volumetric fillers, in addition to enabling the filling of difficult to dispense foods, also reduce downtime to a bare minimum.

Food filling done cost-effectively

Food-grade machines are designed to provide fast, efficient, consistent and hygienic dispensing of products for food filling lines. Multi-Fill’s machines have several key design features that will help to provide these benefits:

- Robust construction: Volumetric fillers need to run for hours at a stretch, dispensing, reliably and consistently throughout. They need to be built sturdy resilient in order to keep running in a variety of conditions and for extended periods. The aim is optimal throughput with minimal maintenance. The machines can operate 24/7.

- Easy cleaning: In the food industry, cleaning is an essential function. A machine’s sanitary requirements should not hold back the production line for too long, however. Staff need to be able to clean thoroughly and have the machine up and running again in the shortest possible time. The best filling machines are designed and built with this in mind. Features such as easy disassembly and re-assembly (no tools needed), minimal moving parts, and tilt-out hoppers, ensure that the cleaning crew can get in and out in record time during product changeovers or routine cleanings.

- Flexibility: Food filling lines need versatile machines that can easily change between a variety of products. The changeover between products must cause enough downtime to affect productivity, so the machines need to be adaptable so that they can be cleaned and filled with new product very quickly.

For more information about Multi-Fill machines and what they can do for your food-filling line, contact us.

Designing a food filling line: Product is king